When it comes to home remodeling and updates, the kitchen tends to be the most popular spot for these plans. It’s not uncommon for people to upgrade their kitchens before they look to upgrade any other part of the home—and manufacturers are keeping up with consumers by continuing to offer more and more appliance features.

Smart home devices of all sorts are evolving to incorporate the latest technologies—from cameras to Bluetooth connectivity—and respond to consumer feedback on how home appliances impact their daily lives. Business Insider Intelligence forecasts that total smart home devices will exceed 1 billion in the US by 2023, smart appliances making up about 100 million of that.

The driving force behind this adoption centers on features that either improve convenience or maximize usability as consumers’ lives continue to struggle with too much to do and not enough time to do it. Appliances now link with smart phones to help improve everything from grocery shopping to the cooking experience.

Challenge

With digital olfaction, odor sensors can be integrated into smart fridges and other home appliances to detect when food may soon spoil and no longer taste good. Or your oven could trigger an alert to take the fish out before it began to burn.

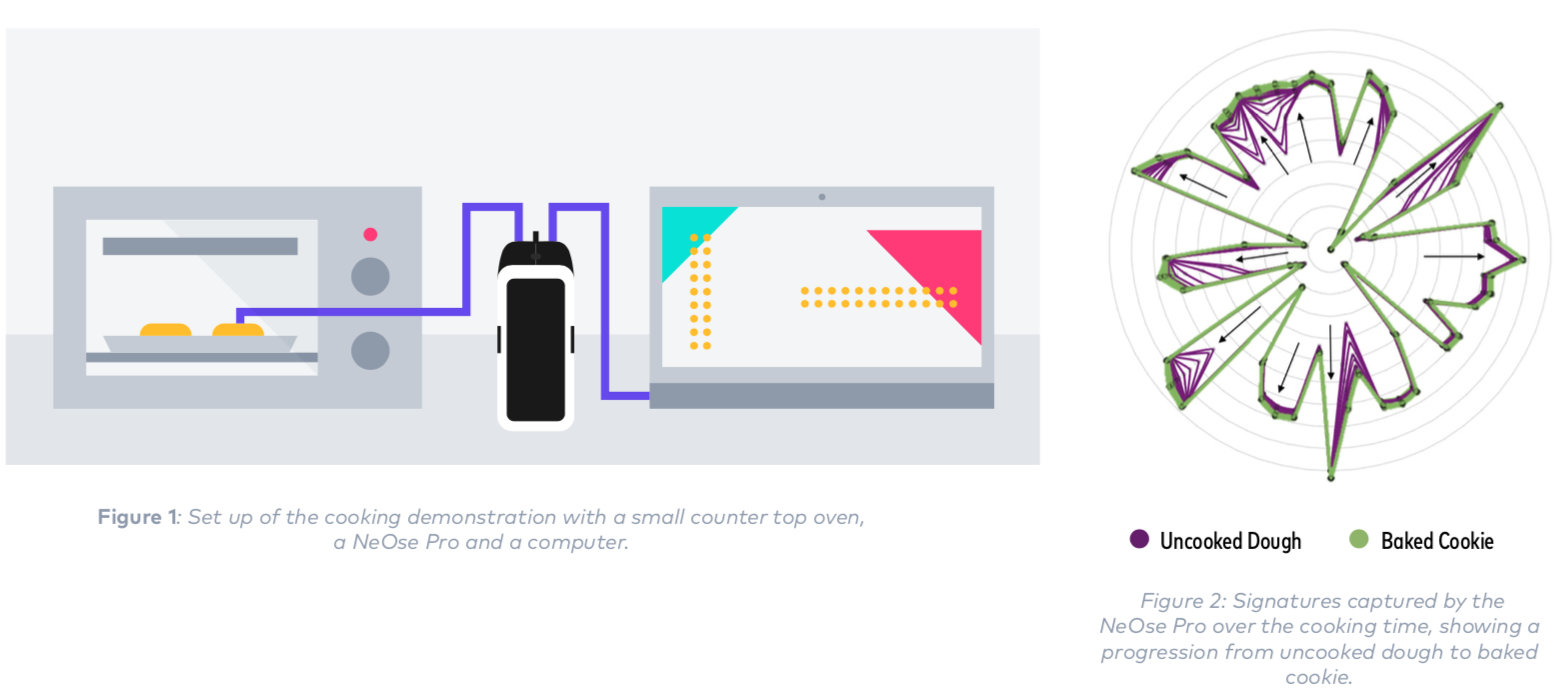

In fact, we’ve used Aryballe’s NeOse Pro to examine these scenarios in action. Using a set-up of our device coupled to a small oven appliance, we were able to distinguish between cookie dough and a baked cookie, all by relying on the odor data collected. Imagine an oven that could produce a perfectly baked chocolate chip cookie every time by automatically turning off once it smells the cookie is done baking.

Solution

Time-based odor analysis depends on understanding the evolution of an odor profile over time. Unlike other uses of digital olfaction, here we’re taking continual measurements to see when an odor signature migrates from the initial signature to the identified ideal cooked profile.

To illustrate this, Aryballe integrated our sensor into a common toaster oven to track the change in odor of raw cookie dough to a baked cookie. This assembly included the toaster oven, an Aryballe sensor, and a computer for real-time monitoring.

In the cooking environment, the device saw a significant variance in olfactory signature replicates between the raw cookie dough and backed cookie profiles. During the cooking demo, we saw a progression in the signature from the raw to cooked signature (Figure 2).

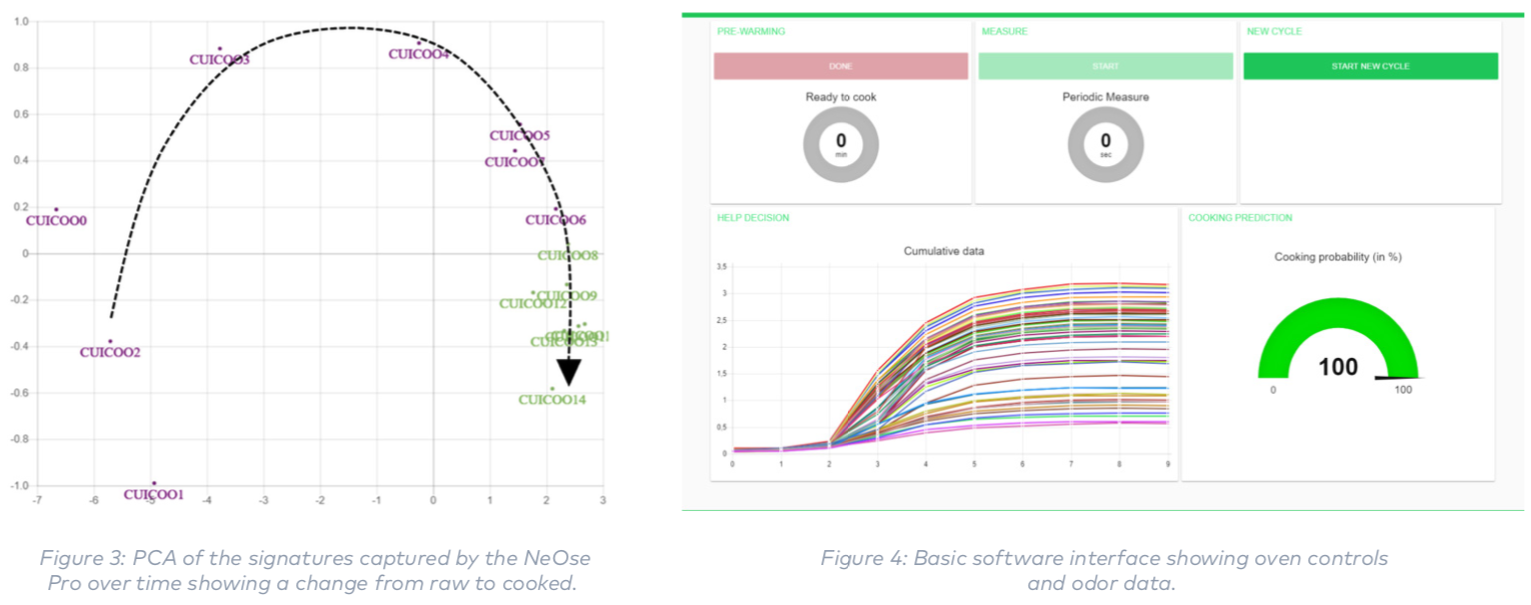

If we look at the clustering results of the ongoing measurements, we can see the movement of the cluster from the raw to cooked (Figure 3).

In this particular demo scenario, Aryballe’s software team developed a basic control platform where you could see the progression of the odor data over the cooking time—enabling an alert to when the olfactive signature had reached the optimum profile (Figure 4).

Conclusion

The results of the tests showed that Aryballe’s digital olfaction technology can be used for time-based odor analysis. While cooking is a primary consumer application of this approach, this approach can apply for other applications like food storage and flavor release.