Evaluating Vanillin Suppliers

Results of classification of various vanillin sources and samples.

Vanilla, one of the world’s most popular flavors, is widely used in food and cosmetic industries, and ranks as the second most expensive spice. Facing growing consumer preferences around natural ingredients, manufacturers in these industries are looking to replace their artificial sources of vanilla with natural ones. However, recent steep increases in vanilla (from 1 to 10 year-over-year) are causing many to either look for alternative replacements for vanilla or to optimize they use vanilla in their products.

The quality and availability of natural vanilla production can be difficult because of the crop’s vulnerability to natural and man-made risks, like disease, natural disasters, early harvest, variability in cultivation intensity (ie. ‘quick curing’), and packaging. Improper harvesting and curing practices due to market demand have increased the pressure on manufacturers to better scrutinize the vanillin content and aroma profiles of raw materials.

In response to these trends, vanillin manufacturers have recently introduced “Bio Vanillin” which is obtained from renewable materials like lignin or other catalytic process. This brings the food and cosmetic industries a cost advantage as it’s priced between natural and artificial sources while still complying with natural ingredient regulations.

Challenge

While vanilla is a unique flavor that cannot be replicated with simple imitation products, food and beverage companies have to deal with a wide variety of natural and artificial compounds to satisfy various market demands at the right price point with proper quality-price ratios.

Although traditional quality control methods use analytical instruments like UV spectrophotometry or gas chroma-tography (liquid or IRMS) to assess these materials, the incumbent technology has limitations.

- The cost of performing a 100% QC with standard Analytical tools (GC) adds significant costs per measurement and would delay material intake due to the time to analysis.

- The bulky equipment is often located in a centralized lab and not portable for warehouse use

- The sensitivity of the equipment to vanillin compounds is not directly related to odor and flavor profiles desired by consumers

These concerns are amplified by the movement to bio vanillin because minor variations from batch to batch that have a high impact on flavor might not be detected in traditional methods.

Solution

Digital olfaction technology from Aryballe allows for raw material identification and classification to identify suppliers and set quality standards in the formulation stage. These standards can then be applied by quality control with portable, handheld devices like the NeOseTM Pro. This ensures factories can quickly and easily determine any tag errors on incoming products and provide early alerts on potential quality control issues before they enter the manufacturing process.

The tests performed with the NeOse Pro were first used to classify different vanillin types: artificial vanillin, bio vanillin, ethyl-vanillin and one natural vanilla sample.

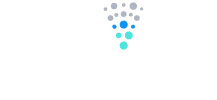

Each raw sample was prepared in 60 ml vials and heated at 60°C for 10 minutes. After this, each sample was tested by the NeOse Pro by sniffing the headspace for 10 seconds. The device uses a patented optical technology to produce a unique signature (Figure 1) of each odor sample in 67 dimensions. Figure 1 shows these signatures generated by this test.

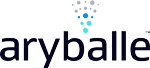

After performing the initial signature capture, software from Aryballe Technologies creates a statistical MDS (Figure 2) which shows the separation of the four samples: artificial vanillin, bio vanillin, ethyl- vanillin and natural vanilla.

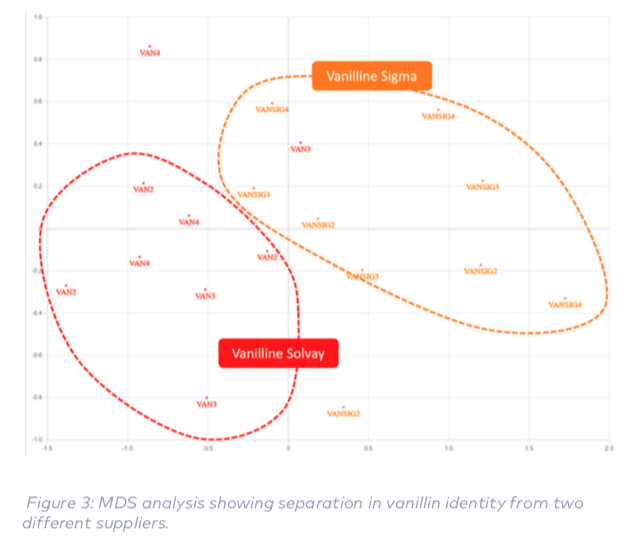

After capturing and characterizing the different signatures for the vanillin, the device was then used to characterize the signatures of artificial vanillin from two different suppliers. After characterizing the signatures, the test was performed on a larger batch of samples from each supplier—as seen in the MDS in Figure 3.

Depending on identification requirements and quality control standards of each manufacturer or factory, one can choose to adjust the separation ratio in identifying the right sample to not only adjust yield but also to narrow down the ratio of following QC process.

Conclusion

These tests show the ability of the NeOse Pro to quickly identify and distinguish various nature of vanillin—adding value to the R&D and formulation process. Moreover, the speed and portability of the device provide a compelling use case for real-time quality control by distinguishing vanillin samples from different suppliers that can meet the manufacturing standards set development.