As a pioneer in digital olfaction, Aryballe utilizes smart sensor hardware and machine learning software to create objective and reliable odor analyses that enable companies to make better decisions based on standardized, measurable data.

For products like scented candles, odor and aroma are critical to the user experience and a negative experience could lead to impacted sales and damage to a company’s brand. Using digital olfaction, Aryballe helps these manufacturers optimize their production and head off potential issues that could lead to a diminished user experience or loss of raw materials.

In a recent study, Aryballe worked with Antique Candle Co. to assess odor signatures related to varied ingredients and the impact of potential contamination during the manufacturing process. With clear data showing the impact of using one ingredient versus another on the final product, Antique Candle Co. can optimize their product development. Likewise, identifying the impacts of potential product contamination helps improve processes to ensure proper equipment maintenance and cleaning to avoid product losses.

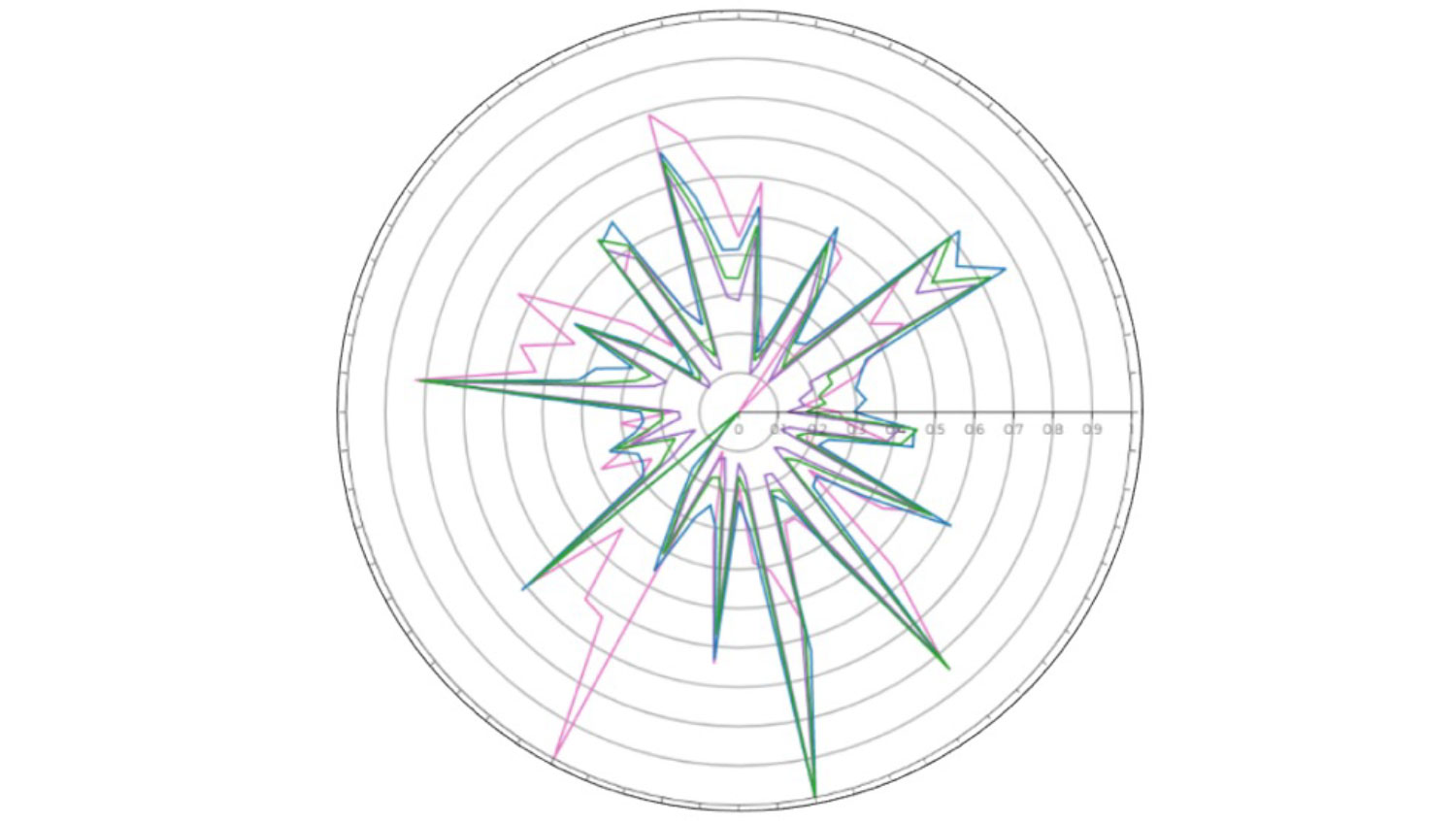

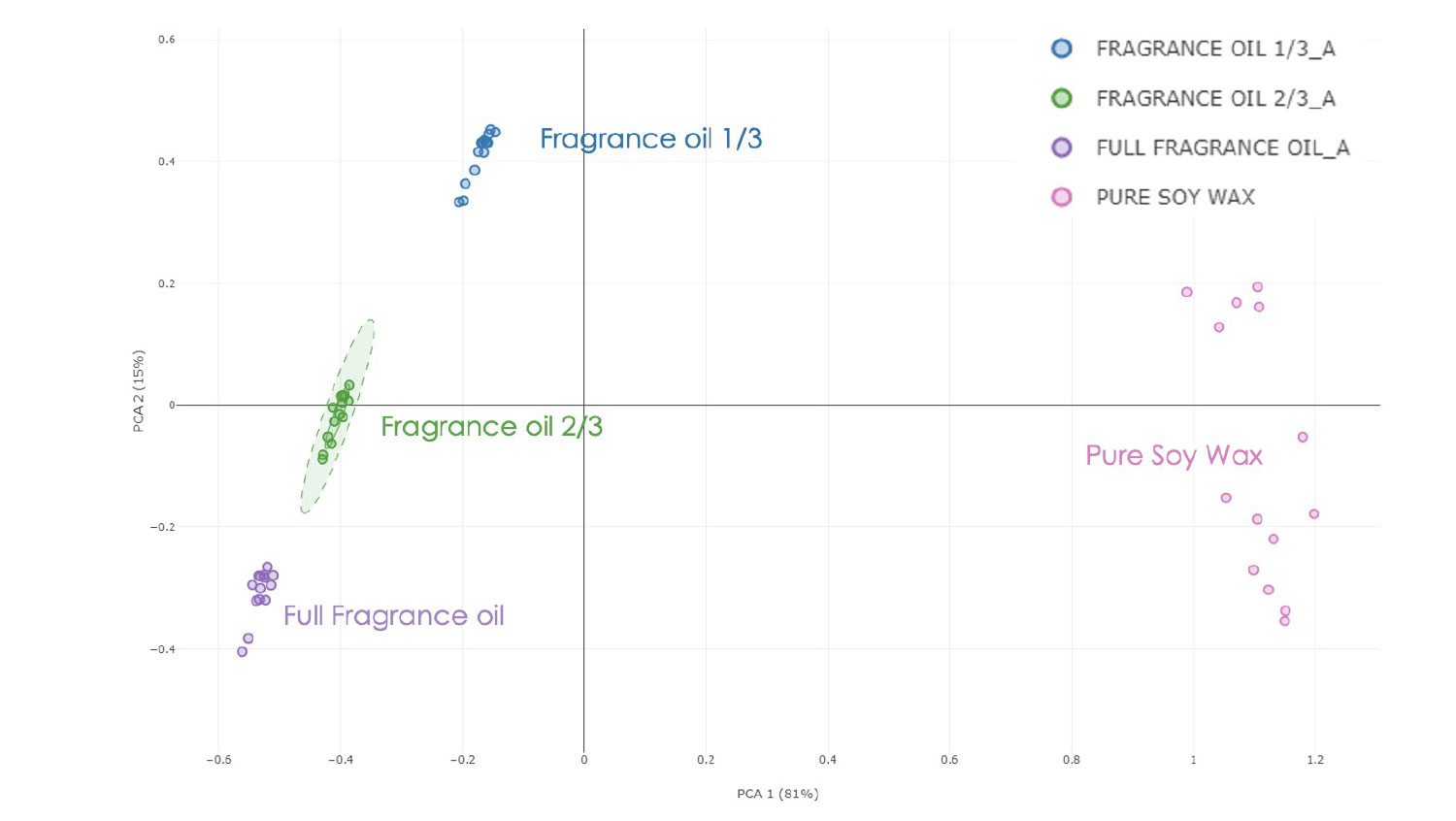

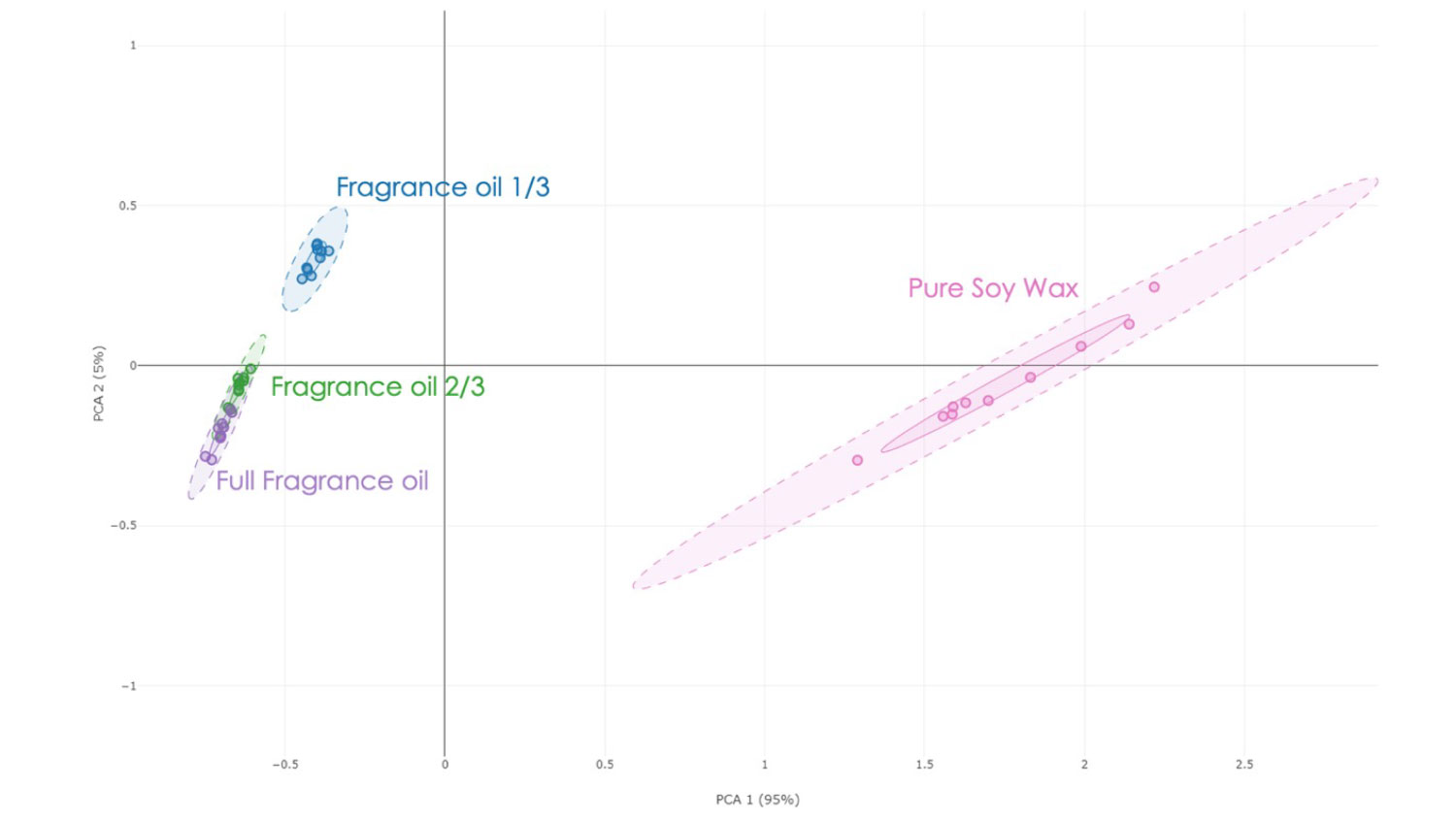

During the study, samples were examined to see the difference in the aroma of pure soy wax versus solids with different concentrations of fragrance oil. We examined solids with the proper fragrance oil dosage, two thirds fragrance dosage, and one third fragrance oil dosage. At room temperature, there is a clear similarity between the signature for each of the fragrance oil samples as you would expect, while the pure soy wax has a distinct signature.

However, in examining the principal component analysis, we can see that the four samples are easily distinguished from each other.

As samples were heated to 80°C (about the temperature of a burning candle), we saw that there was still a clear distinction between the pure soy wax and one third fragrance oil, but that the pure fragrance oil and two thirds fragrance oil began to mix and become indistinguishable.

These findings can be used in product development to optimize the balance between product materials and consumer experience.

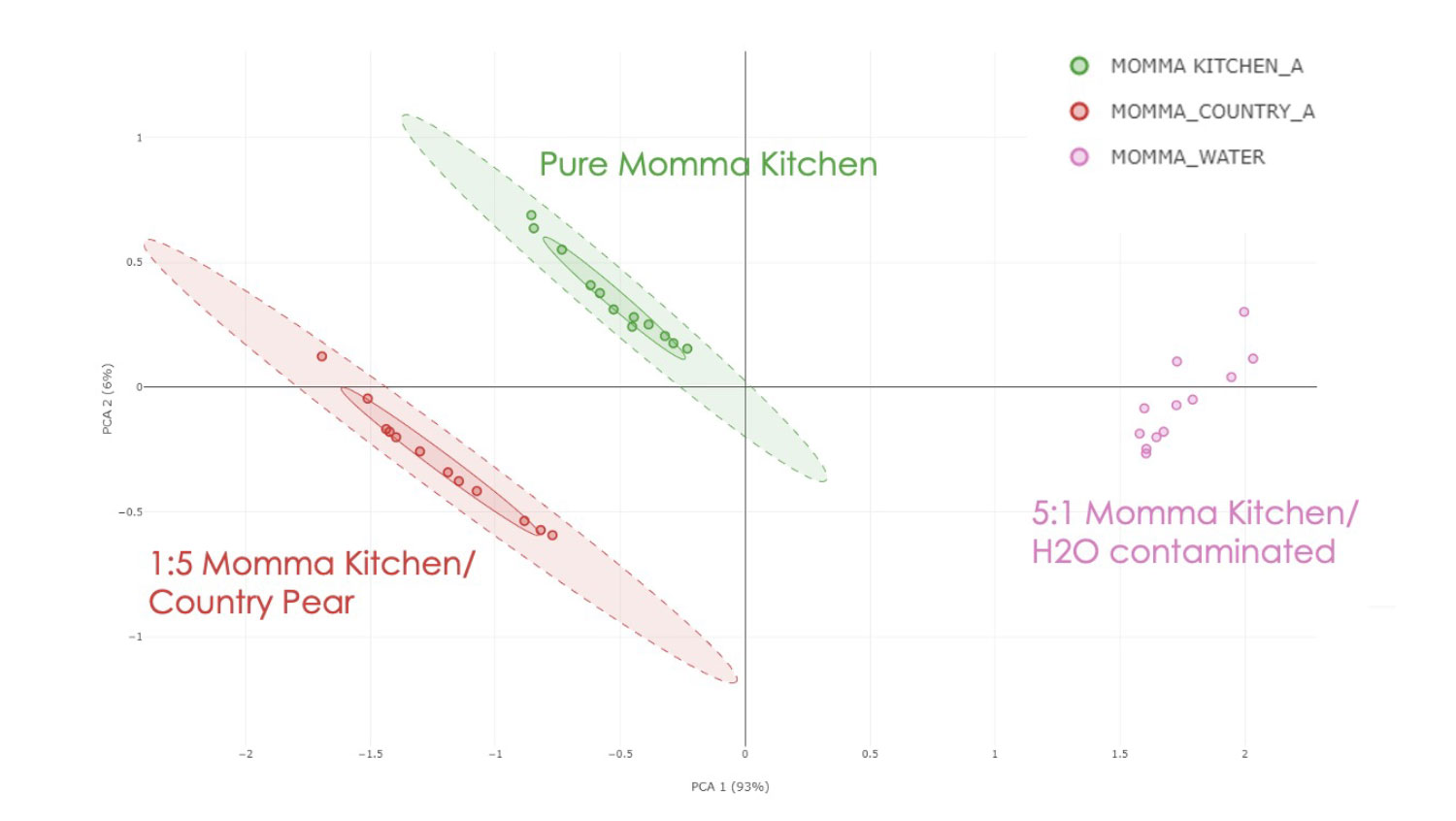

In a second part of this study, we examined liquid samples of pure fragrance oil versus two different types of potential contamination that could occur when processing a new batch on recently cleaned or used equipment—water and another fragrance oil. This test would be done on fragrance oil as a raw material quality control check prior to making any candles.

Once again there was clustering in the PCA—indicating that the Aryballe device could clearly distinguish between the samples and thus could assist not only in detecting contamination versus the good sample, but also opens the potential to tell the manufacturer the source of the contamination—either water left in the system from a flush out or fragrance oil from a previous run.

This study points to how digital olfaction is assisting in the digital transformation of the fragrance industry. By leveraging odor analytics, there is significant potential across the sector for cost savings, waste reduction and better customer experiences. Digital olfaction can deliver objectivity and consistency at a level not currently possible with human analysis, creating better products, eliminating defective or substandard inputs, and improving the research and development process.